|

|

Old Stuff from the Oil Fields

(The vanishing outdoor oil museum of the San Joaquin Valley)

Jack Plants and Jack Lines - Drilling a producing oil well on the west side of the San Joaquin Valley in the late 1800s was only the first challange facing a small oil company, as the owners also needed to sell their oil at a profit in distant Bakersfield. After all, they could not afford to stay in business very long if it cost them 29 cents to produce a barrel of oil and deliver it town, yet the best they could do is sell their oil at market for a meager 22 cents a barrel.

Jack Plants and Jack Lines - Drilling a producing oil well on the west side of the San Joaquin Valley in the late 1800s was only the first challange facing a small oil company, as the owners also needed to sell their oil at a profit in distant Bakersfield. After all, they could not afford to stay in business very long if it cost them 29 cents to produce a barrel of oil and deliver it town, yet the best they could do is sell their oil at market for a meager 22 cents a barrel.

The appearance in California in the early 1890s of the "jack-line" system of producing wells provided a huge stimulus to the industry by allowing operators to pump from multiple wells using only a single steam or gas engine. The cost savings were enormous compared to the expense of outfitting each well with its own engine.

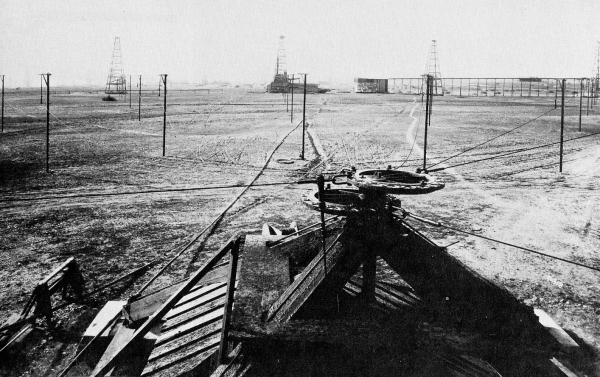

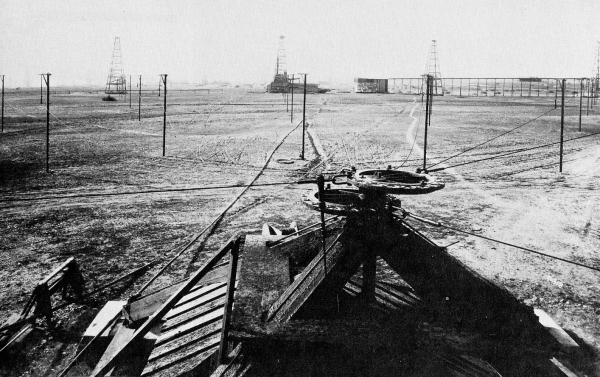

The heart of the jack-line system is the Allen Patent Pumping Unit, which was introduced in the Pennsylvania oil fields by former blacksmith and occassional oil field investor George Allen in 1884. Allen's invention consisted of a belt-driven wheel mounted on a vertical shaft with the hub offset, instead of running through the center ofg the wheel, as it would on a wagon. This wheel, called an "eccentric", rotated within a second wheel, called the "slip wheel". Shackled to the slip wheel were taut steel cables, called "jack lines", which stretched from the slip wheel to oil wells balanced around the pumping unit. (The eccentric from the Kern County Museum jack plant is shown in the photo above.) The heart of the jack-line system is the Allen Patent Pumping Unit, which was introduced in the Pennsylvania oil fields by former blacksmith and occassional oil field investor George Allen in 1884. Allen's invention consisted of a belt-driven wheel mounted on a vertical shaft with the hub offset, instead of running through the center ofg the wheel, as it would on a wagon. This wheel, called an "eccentric", rotated within a second wheel, called the "slip wheel". Shackled to the slip wheel were taut steel cables, called "jack lines", which stretched from the slip wheel to oil wells balanced around the pumping unit. (The eccentric from the Kern County Museum jack plant is shown in the photo above.)

The eccentric in this diagram is green, the slip wheel yellow and the jack lines red. Because the eccentric can rotate, but the slip wheel cannot, the slip wheel must move back and forth, thus pulling the jack lines back and forth as well.

|

Because jack lines pulled on the slip wheel from all sides, as the eccentric within rotated, the slip wheel could only move back and forth. This meant the jack lines got pulled back and forth without rotating either.

The jack lines were shackled on the other end to units called "grasshoppers", or "jacks". As the jack lines pulled on the grasshoppers, then slacked off, this motion caused the grasshoppers to move rods in the oil wells up and down, like the pumping jacks that we describe elsewhere, to literally lift oil out of the ground. Short upright supports called "doll heads" kept the jack lines from touching the ground, and long supports called "swing poles" elevated the Jack lines to the most efficient height for powering the jacks. (A grasshopper at the Kern County Museum Jack Plant is shown on the right.) The jack lines were shackled on the other end to units called "grasshoppers", or "jacks". As the jack lines pulled on the grasshoppers, then slacked off, this motion caused the grasshoppers to move rods in the oil wells up and down, like the pumping jacks that we describe elsewhere, to literally lift oil out of the ground. Short upright supports called "doll heads" kept the jack lines from touching the ground, and long supports called "swing poles" elevated the Jack lines to the most efficient height for powering the jacks. (A grasshopper at the Kern County Museum Jack Plant is shown on the right.)

Jack Plants, as they were called, were tricky to set up, but the cost savings were substantial. When jack plants first appeared in the Pennsylvania oil fields in the late 1880s, Allen's pumping unit cost $100 to $300, whereas the engine to drive a pumping jack might cost $2,000 to $3,000. If the grasshoppers arranged around the pumping unit were properly balanced with counter weights, so as to equalize stress on the system, one could run up to 20 wells from a plant as far as half a mile away, with the eccentric delivering 12 to 17 rotations a minute, depending on the volume and gravity of the oil, and the depth and distance of the well.

There were still several jack plants operating in the San Joaquin Valley just a few years ago, but all of them have pretty much been replaced by individual pump jacks driven by either diesel or electric engines, the latter of course being more environmentally friendly. Bruce Petty has a site with some nice pictures of jack plants that were still operating 30 years ago at Kern River and Simi Valley oil fields. Also, Antique Oil Field Equipment has some recent pictures of modern jack plants in Oklahoma and northern Texas.

|

Photo of an old jack plant somewhere in Kern County. Note the jack lines running out to distant grasshoppers that can't even be seen. This eccentric is very similar to the one at the Kern County Museum.

Diagram of a Jack Plant with a layout similar to the working plant at the Kern County Museum.

|

|

|